Robotic EMAT Inspection

By , 05 September 2024

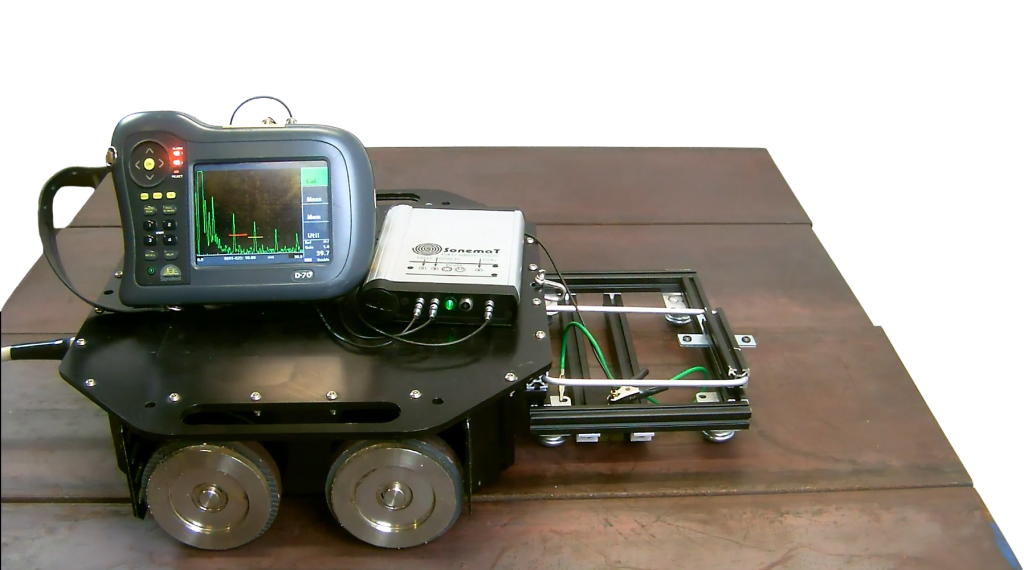

In the ever-evolving field of non-destructive testing (NDT), robotic EMAT inspections are transforming how industries perform maintenance and quality control. Sonemat, a leader in EMAT technology, offers advanced solutions for semi and fully automated robotic inspections. Our tailored EMAT probes and electronics are designed to integrate seamlessly with various robotic platforms, providing precise and reliable data in challenging environments.

The Future of NDT with Robotic EMAT Inspections

Robotic inspections are becoming increasingly essential in industries where safety, efficiency, and precision are paramount. By combining the advantages of electromagnetic acoustic transducer (EMAT) technology with the flexibility of robotic systems, Sonemat delivers cutting-edge solutions that enhance the capabilities of automated NDT processes. Our expertise in adapting EMAT probes and electronics for robotic applications ensures that clients receive the most effective and reliable inspection tools available.

Key Applications of Robotic EMAT Inspections

1. Automated Thickness Gauging

Robotic EMAT inspections provide accurate thickness measurements in difficult-to-reach areas, reducing the need for manual intervention. This is especially beneficial in hazardous environments where human access is limited.

- Advantages:

- Precise, non-contact measurement

- Increased safety for operators

- Enhanced efficiency in data collection

2. Corrosion and Erosion Monitoring

Monitoring corrosion and erosion in real-time is crucial for maintaining the integrity of critical infrastructure. Robotic EMAT systems can perform continuous monitoring, detecting early signs of degradation and preventing potential failures.

- Benefits:

- Continuous, real-time monitoring

- Early detection of corrosion and erosion

- Data-driven maintenance planning

3. Defect Detection and Weld Inspection

Robotic EMAT systems excel in detecting defects such as cracks and inclusions, as well as inspecting weld quality. These systems can navigate complex geometries and surfaces, ensuring comprehensive inspections.

- Key Features:

- High sensitivity to defects

- Capability to inspect complex geometries

- Reliable performance in various conditions

Sonemat’s Solutions for Robotic EMAT Inspections

Adaptable EMAT Probes

Sonemat offers a range of adaptable EMAT probes designed for integration with various robotic platforms, including crawlers, scanners, and drones. Our probes are engineered for durability and precision, ensuring reliable performance in diverse applications.

- Key Products:

- Shear Wave EMATs: Ideal for thickness gauging and defect detection.

- Longitudinal Wave EMATs: Suitable for general material characterization.

- Guided Wave EMATs: Effective for long-range inspections.

Customised EMAT Electronics

Our customised EMAT electronics are designed to enhance the capabilities of robotic systems. These electronics provide high-quality signal processing and data acquisition, ensuring accurate and reliable results.

- Features:

- High sensitivity and signal processing

- Compact and lightweight designs

- Integration with various robotic platforms

Toneburst Pulser-Receiver TBPR-1000

The Toneburst Pulser-Receiver TBPR-1000 is a versatile product designed to work with our range of guided-wave EMATs (SH EMATs, Lamb, Rayleigh) across a frequency range of 20kHz to 1MHz. This battery-powered device can be controlled via dials or a computer, offering a semi-automated setup with Sonemat’s software. It also features built-in analogue to digital conversion (ADC) for precise data acquisition.

- Benefits:

- Supports a wide frequency range (20kHz to 1MHz)

- Battery-powered for field portability

- Dual control options: manual dials or computer interface

- Semi-automated setup with Sonemat’s software

- Built-in ADC for accurate data acquisition

Applications Across Various Industries

1. Oil and Gas

Robotic EMAT inspections are invaluable in the oil and gas industry for monitoring pipelines and storage tanks. These inspections help prevent leaks and ensure the structural integrity of critical infrastructure.

- Examples:

- Pipeline corrosion monitoring

- Storage tank integrity assessments

- Offshore platform inspections

2. Power Generation

In power generation, robotic EMAT systems provide essential data for maintaining boilers, turbines, and other critical components. These inspections ensure the reliability and efficiency of power plants.

- Benefits:

- Real-time monitoring of high-temperature components

- Detection of stress and fatigue in turbines

- Enhanced safety and reliability

3. Aerospace

Robotic EMAT inspections in the aerospace industry help maintain the safety and performance of aircraft components. These inspections can detect flaws and ensure the structural integrity of critical parts.

- Applications:

- Inspection of aircraft fuselage and wings

- Monitoring of turbine blades

- Quality control of aerospace components

Why Choose Sonemat?

Choosing Sonemat for your robotic EMAT inspections means partnering with a leader in NDT innovation. Our tailored solutions and extensive experience ensure that you receive the most effective and reliable tools for your inspection needs.

- Expertise: Nearly 20 years of experience in NDT and EMAT technology.

- Innovation: Cutting-edge solutions that enhance the capabilities of robotic inspections.

- Customer Support: Comprehensive support from initial consultation to ongoing maintenance.

Partner with Sonemat for Advanced Robotic EMAT Solutions

If you’re looking to enhance your inspection capabilities with advanced robotic EMAT solutions, Sonemat offers the expertise and innovative products you need. Our adaptable EMAT probes and customized electronics ensure precise, reliable inspections in various industries. Contact us today to learn more about our products and how we can assist you in achieving superior results.

FAQs

What types of robots can your EMAT probes be integrated with?

Our EMAT probes can be integrated with various robotic platforms, including crawlers, scanners, and drones.

How do robotic EMAT inspections improve safety?

Robotic EMAT inspections reduce the need for human intervention in hazardous environments, enhancing safety for operators.

Can your EMAT systems be customized for specific applications?

Yes, we offer customized solutions to meet the unique requirements of your inspection needs. Contact us to discuss your specific applications.